Edible Oil Cap Mold

2023-05-11 | Company News

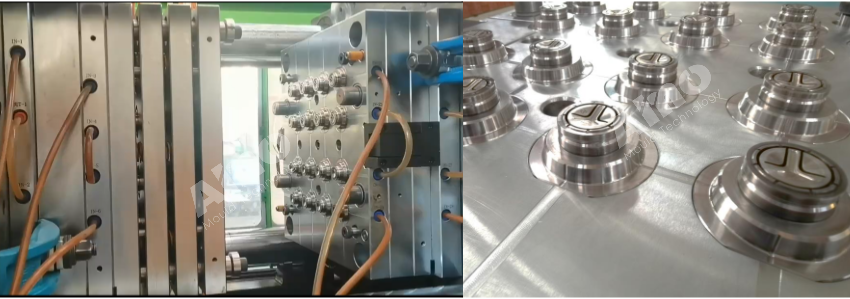

We just finished a 38mm edible oil cap production line,including cap mold, injection machine and cap assembling machine.

For cap mold, use stainless steel S136 with full hot runner system( hot runner can be used Husky,Yudo, Mastip)

It is 16 cavities edible oil cap mold( We can do 16 cavities, 24 cavities, 32 cavities and 48 cavities as your required)

We have strictly Mould&sample QC system,such as CMM inspection of each plate parallelism, each hole position and coaxxlaity, core & cavity key assembling dimensions,mass production for hours to ensure running stable. Sample QC including high pressure vacumm test for sealing, pull of strength test,key dimension inspection, drop test of bottle.

Auto upper cap and bottom cap assembling machine, 6000pcs per hour.

Related News

contact us

Get a Free Quote

Our engineers are available to talk you through each of our offerings. We’ll be sure to reply you within 48hours with detail quotation data. Fill in the form below with as much detail as possible, we’ll get back to you promptly.

SUBMIT